The first G-type engine, designated G80ME-C1, has a design that follows the principles of the large-bore Mk-9 engine series that MAN Diesel & Turbo introduced in 2006. The G-type is designed with a longer stroke to reduce engine speed, thereby paving the way for ship designs with unprecedented high-efficiency.

Ole Grøne, Senior Vice President Low-Speed Sales and Promotions, MAN Diesel & Turbo, said: “MAN Diesel & Turbo always follows developments in the shipping market closely and we have kept a close eye on the trend for fuel optimisation in recent years. As such, we have experienced great interest in the G-type engine during extensive consultation with industry partners and are currently working on a variety of projects with shipyards and major shipping lines. As a result, we have reached the conclusion that the introduction of the G-type engine programme is both viable and timely.”

Ole Grøne, Senior Vice President Low-Speed Sales and Promotions, MAN Diesel & Turbo, said: “MAN Diesel & Turbo always follows developments in the shipping market closely and we have kept a close eye on the trend for fuel optimisation in recent years. As such, we have experienced great interest in the G-type engine during extensive consultation with industry partners and are currently working on a variety of projects with shipyards and major shipping lines. As a result, we have reached the conclusion that the introduction of the G-type engine programme is both viable and timely.”

Grøne added: “The G-type is an ultra-long-stroke engine and represents the biggest development within our engine portfolio since the successful introduction of the ME electronic engine within the last decade.”

Rationale for G-type introduction

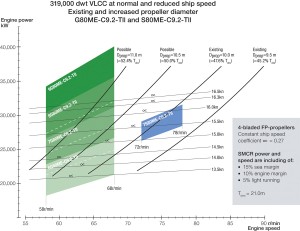

Tankers and bulk carriers have traditionally used MAN B&W S-type engines with their long stroke and low engine speed as prime-movers, while larger container vessels have tended to use the shorter-stroke K-type with its higher engine speed.

Larger container vessels, in recent years, have also been specified with S80ME-C9 and S90ME-C8 engines because of the opportunity they offer to employ larger propeller diameters. Following efficiency optimisation trends in the market, MAN Diesel & Turbo has also thoroughly evaluated the possibility of using even larger propellers and thereby engines with even lower speeds for the propulsion of tankers and bulk carriers.

Such vessels may be compatible with propellers with larger diameters than current designs, and facilitate higher efficiencies following adaptation of the aft-hull design to accommodate a larger propeller. It is estimated that such new designs offer potential fuel-consumption savings of some 4-7%, and a similar reduction in CO2 emissions. Simultaneously, the engine itself can achieve a high thermal efficiency using the latest engine process parameters and design features.

G-type progress

MAN Diesel & Turbo reports that design work for the first G-type is already in progress and final drawings for the structure, moving parts and fuel equipment are scheduled to be ready for delivery in mid-2011. The delivery of piping and gallery drawings is scheduled to follow in the second half of 2011, assuming final order confirmation has been received by the end of 2010.

MAN Diesel & Turbo also confirms that other G-type engines of different cylinder diameter will be introduced on demand.

More information could be found here!