Direct Drive

Direct Drive

One of the most common layouts for larger Tankers, Bulkers, Container and vehicle carriers is a layout with one or two cross-head main engines with direct drive with a fixed propeller. The main engine is directly connected with the propeller and the speed of the engine (90-105 rpm) is also the speed of the propeller. The thrust block in this design forwards the energy from the propeller into the hull and not into the engine. This is a simple and efficient design. (See illustration to the left)

Double Engine Single Shaft

Medium sized ships and specialized vessels this layout is common. Two medium speed engines are connected to a gear box that reduces the speed to optimum propeller speed. A clutch is used to disconnect one engine if not needed and the system is equipped with a cpp (controllable pitch propeller) that allows the engines to be operated at optimum speed at any work load. The propeller pitch is controlled by the OD box from the bridge or control room. This layout offers a good flexibility. (See illustration to the right)

“Father-Son” layout

A variant of the “Double Engine Single Shaft” is illustrated in the picture to the left. In this case a smaller engine is connected to shaft of the main engine.

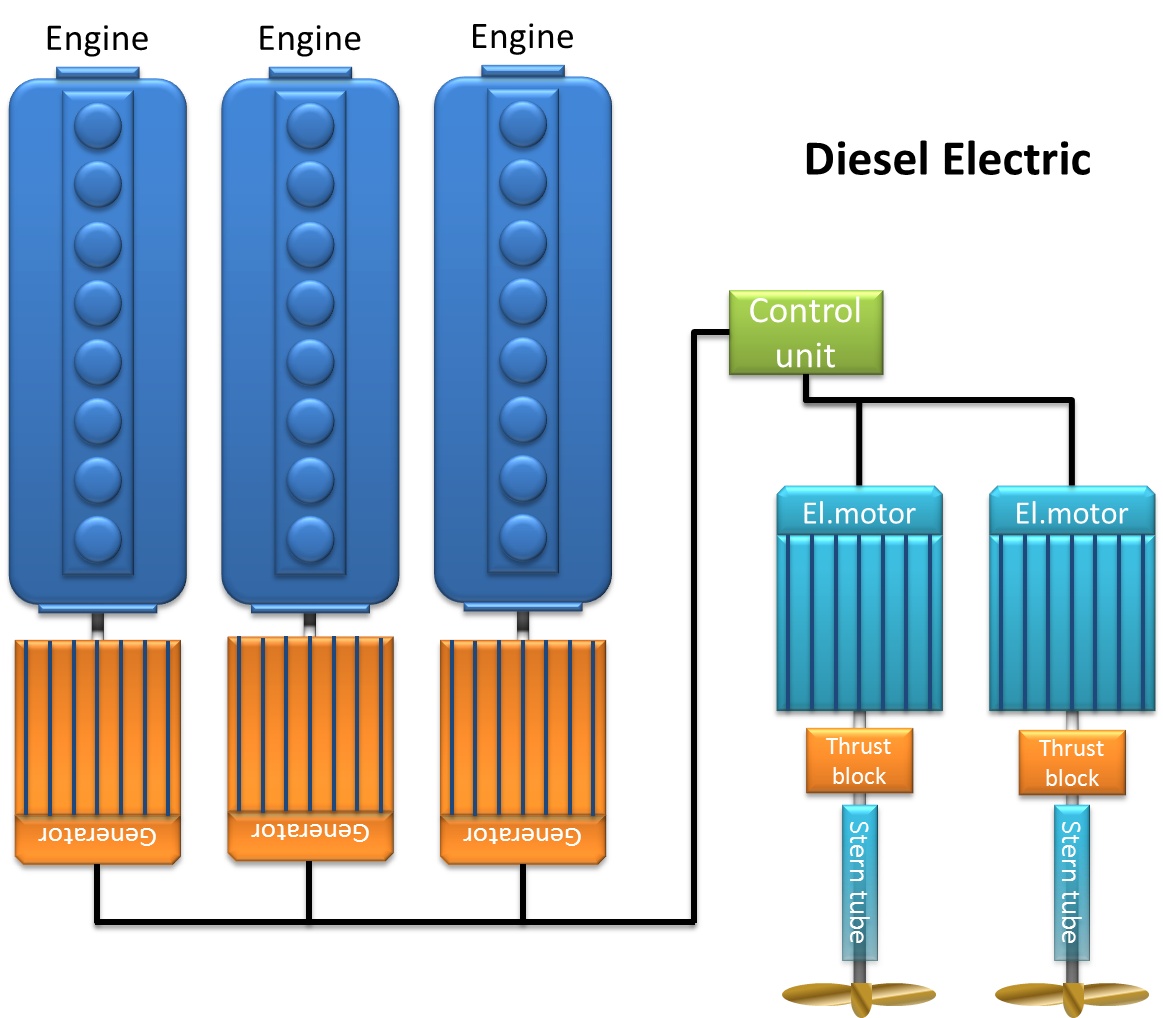

Diesel-Electric

Diesel-Electric

The Diesel-Electric layout is commonly used on ice breakers and cruise ships. The basic principle of the this layout is that diesel medium speed engines are used to run generators that powers electric motors for propulsion. It offers great flexibility as the engines can be place where you have space.

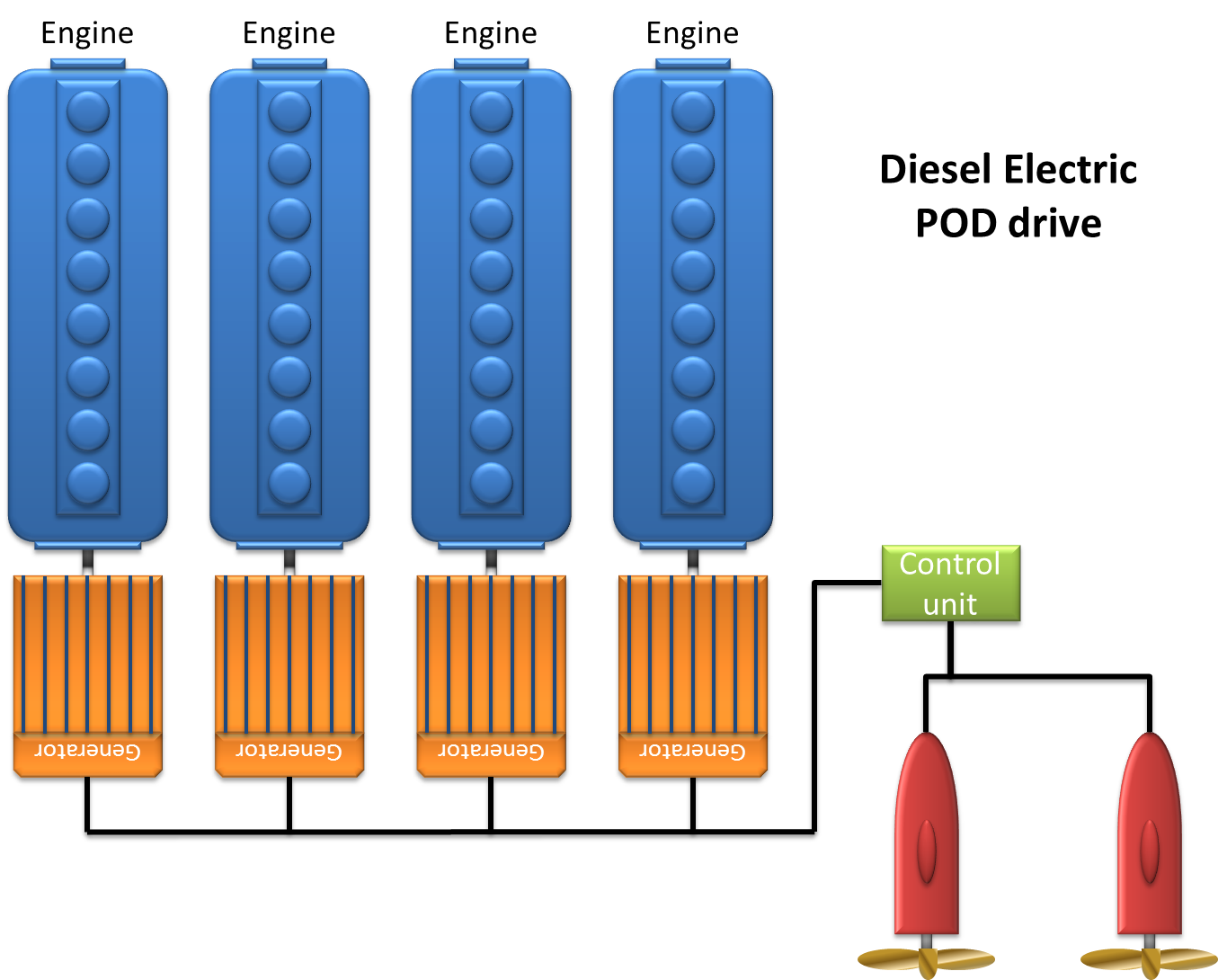

A variant is the “POD” propulsion system. In this case the electric motors is mounted inside a”POD” that a fitted under the hull. The POD propulsion system offers great maneuverability. (See illustrations below)